Bye Bye Lactobacillus! UV Eliminates Heat Resistant Molds & Thermotolerant Organisms

Home /Bye Bye Lactobacillus! UV Eliminates Heat Resistant Molds & Thermotolerant Organisms

Bye Bye Lactobacillus! UV Eliminates Heat Resistant Molds & Thermotolerant Organisms

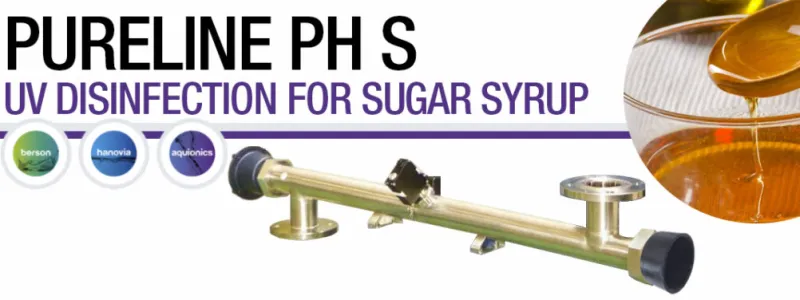

With the rise in popularity in Hard Seltzers, UV applications for sucrose disinfection have become an extremely practical solution! UV disinfection provides a solution to eliminate spoilage organisms such as Lactobacillus, Alicyclobacillus, and heat resistant molds (HRM’s) that survive pasteurization! Our Pureline S system provides an inline UV treatment solution that is installed directly in existing piping or recirculated on sucrose storage tanks. Beverage producers can leverage this technology to :

- Extend product shelf life,

- Eliminate off flavors and odors, and

- Ensure product consistency batch-to-batch.

Traditionally UV technology has been limited in this application. UV light does not penetrate sweetener solutions as easily as applications commonly seen in ingredient water treatment. The Pureline S system utilizes a slender vessel design coupled with unique hydraulics to vigorously mix the product inside of the chamber. This allows the sweetener solution to come into closer contact with the lamps housed inside their high intensity UV system. The result is disinfection of difficult to inactivate microorganisms.

Unlike traditional UV systems, this novel technology can withstand the higher temperatures commonly seen in sugar syrup applications (up to 176F). Older technologies were limited to a maximum operating temperature of 104F, which made the technology unviable.

Lactobacillus, Alicyclobacillus, and HRM’s are resilient organisms. Beverage spoilage organisms such as these can often survive low acid, low oxygen, and high alcohol environments making them ubiquitous. This new technology finally provides beverage facilities with a tool for eliminating these spoilage organisms from sweetener solutions.

Learn more about the inactivation of guaiacol-producing Alicyclobacillus in sucrose here or contact PT. PKMG.

- Extend product shelf life,

- Eliminate off flavors and odors, and

- Ensure product consistency batch-to-batch.

Traditionally UV technology has been limited in this application. UV light does not penetrate sweetener solutions as easily as applications commonly seen in ingredient water treatment. The Pureline S system utilizes a slender vessel design coupled with unique hydraulics to vigorously mix the product inside of the chamber. This allows the sweetener solution to come into closer contact with the lamps housed inside their high intensity UV system. The result is disinfection of difficult to inactivate microorganisms.

Unlike traditional UV systems, this novel technology can withstand the higher temperatures commonly seen in sugar syrup applications (up to 176F). Older technologies were limited to a maximum operating temperature of 104F, which made the technology unviable.

Lactobacillus, Alicyclobacillus, and HRM’s are resilient organisms. Beverage spoilage organisms such as these can often survive low acid, low oxygen, and high alcohol environments making them ubiquitous. This new technology finally provides beverage facilities with a tool for eliminating these spoilage organisms from sweetener solutions.

Learn more about the inactivation of guaiacol-producing Alicyclobacillus in sucrose here or contact PT. PKMG.